A legally binding agreement between Mercedes-Benz and H2 Green Steel calls for the yearly delivery of around 50.000 tonnes of green steel to the automaker’s European manufacturing. Mercedes-Benz also inked a memorandum of understanding with H2 Green Steel for the possible supply of green steel made in North America, marking a trailblazing effort on their part.

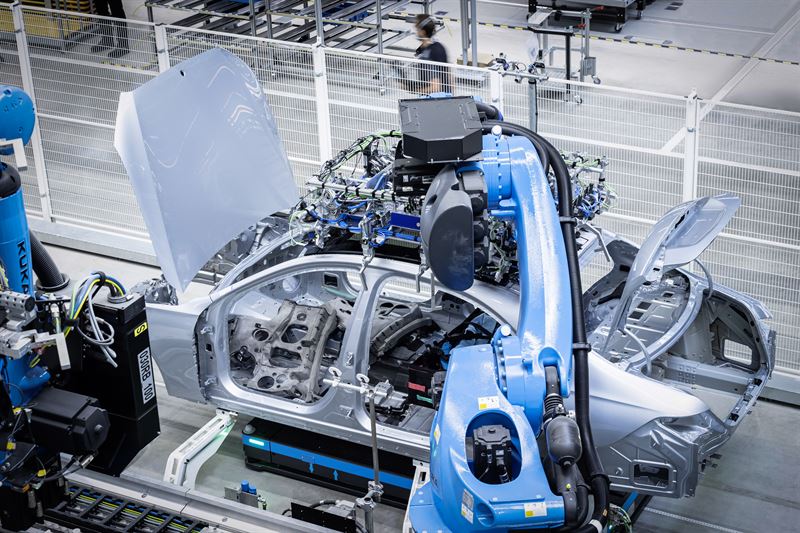

Mercedes-Benz invested in H2 Green Steel early on and confirmed early on through an offtake arrangement that there was a market for green steel. This arrangement has now been strengthened into a legally binding agreement covering quantities of around 50.000 tonnes annually, which will be produced at the green hydrogen-powered iron and steel mill owned by H2 Green Steel in Boden, northern Sweden. Mercedes-Benz makes yet another effort to lessen the environmental effect of making cars by utilizing premium steel that is produced sustainably.

“H2 Green Steel was founded as a result of early automobile industry leaders like Mercedes-Benz warning that the pace of change in the steel sector was too sluggish for them to reach their climate commitments. We have a partner in Mercedes Benz with whom we can set new standards for supply chain emissions, circularity, and social sustainability. According to Henrik Henriksson, CEO of H2 Green Steel, “They are a very strong player to coordinate with for our European operations, but inevitably also as we endeavor into the steel value chain in North America.”

Mercedes-Benz is strongly committed to circularity, and along with the Boden factory, they will build a closed-loop system for the recycling of scrap steel. This is in addition to the sustainable manufacturing of green steel. In addition, the relationship enables H2 Green Steel to benefit from Mercedes-Benz’s broad experience and proficiency in supply chain human rights.

Mercedes-Benz and H2 Green Steel are speeding up the development of a decarbonized, local, and resilient steel supply chain with the supply agreement for around 50.000 tonnes of nearly CO2-free steel for our production sites in Europe. The establishment of a sustainable steel supply chain in North America is one of the goals of our partnership at the same time. This is a crucial step in making the automotive sector more resilient and sustainable, according to Markus Schäfer, Member of the Board of Management at Mercedes-Benz Group AG and its Chief Technology Officer for Development & Procurement.

The two businesses have also committed to cooperating in order to ensure a long-term supply of green steel manufactured in North America for Mercedes-Benz’s production facilities in North and South America, using the collaboration in Europe as the basis. By doing this, the businesses will show that a green steel supply chain is practical and beneficial.

As the steel value chain continues to decarbonize globally, Henriksson says, “We have spoken to various stakeholders in both Canada and the US for some time, and the potential of utilizing an extensive supply of renewable energy for the manufacturing of green hydrogen and green sponge iron which could support a sustainable steel production is an intriguing prospect for H2 Green Steel.